How Epoxy Spray Coating Extends the Lifespan of Your Pipes

Maintaining the integrity of pipe systems is crucial for many industries, including plumbing, water treatment, and oil & gas. Over time, pipes are subjected to various environmental factors, leading to corrosion, leaks, and structural wear. One effective solution to these issues is internal pipe coating with epoxy spray. This advanced technology provides a protective layer that significantly extends the lifespan of your pipes, while also offering numerous benefits.

Corrosion Protection

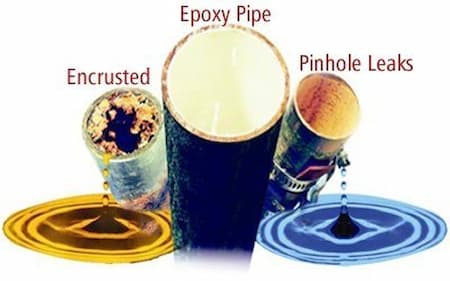

One of the primary reasons for pipe degradation is corrosion, which occurs when metals react with chemicals or moisture in their environment. Corrosion weakens pipes, causing cracks and leaks over time. Epoxy spray for pipes forms a durable barrier inside the pipe, preventing corrosive elements from coming into contact with the metal. This protective coating is particularly valuable in industries where pipes are exposed to harsh chemicals, high moisture levels, or extreme temperatures. By sealing the internal surface, epoxy spray minimizes the risk of rust and corrosion, thus enhancing pipe longevity.

Leak Prevention

Leaks are a common issue in aging pipes, often leading to costly repairs and operational downtime. They can also pose health and environmental risks, especially in industries dealing with water supply, wastewater, or hazardous materials like oil and gas. Internal pipe coating with epoxy addresses this problem by filling in minor cracks and defects within the pipe's interior. Once the epoxy spray cures, it creates a seamless, impermeable layer that effectively seals leaks and prevents future occurrences. This not only improves the performance of the pipes but also reduces the need for frequent repairs or replacements, further extending the life of the entire system.

Wear and Tear Resistance

Pipes, especially in industrial settings, endure constant use, exposure to high pressure, and abrasive materials flowing through them. This leads to gradual wear and tear, decreasing the efficiency of the pipe system over time. Epoxy spray coating enhances the pipe's resistance to such stress factors by creating a smooth, durable internal surface. It reduces friction, which can cause internal damage over time, and protects against abrasions caused by materials moving through the pipes. This protective layer strengthens the pipe's structure, preventing the need for premature replacements.

Cost-Effective and Efficient Solution

For industries such as plumbing, water treatment, and oil & gas, completely replacing damaged pipes can be a costly and disruptive process. By opting for epoxy spray for pipes, companies can restore and reinforce their existing infrastructure without the expense and inconvenience of full pipe replacement. Epoxy coating is a non-invasive method that minimizes downtime while providing long-term results. Its ability to extend pipe longevity and prevent leaks and corrosion makes it a cost-effective solution for maintaining pipe systems.

In conclusion, epoxy spray coating is an ideal choice for protecting pipes against corrosion, leaks, and wear. By enhancing corrosion protection and offering increased resistance to daily stressors, it significantly extends the service life of pipes across various industries. Whether in plumbing, water treatment, or oil and gas, epoxy spray provides a reliable, long-lasting solution that ensures operational efficiency and reduces maintenance costs.